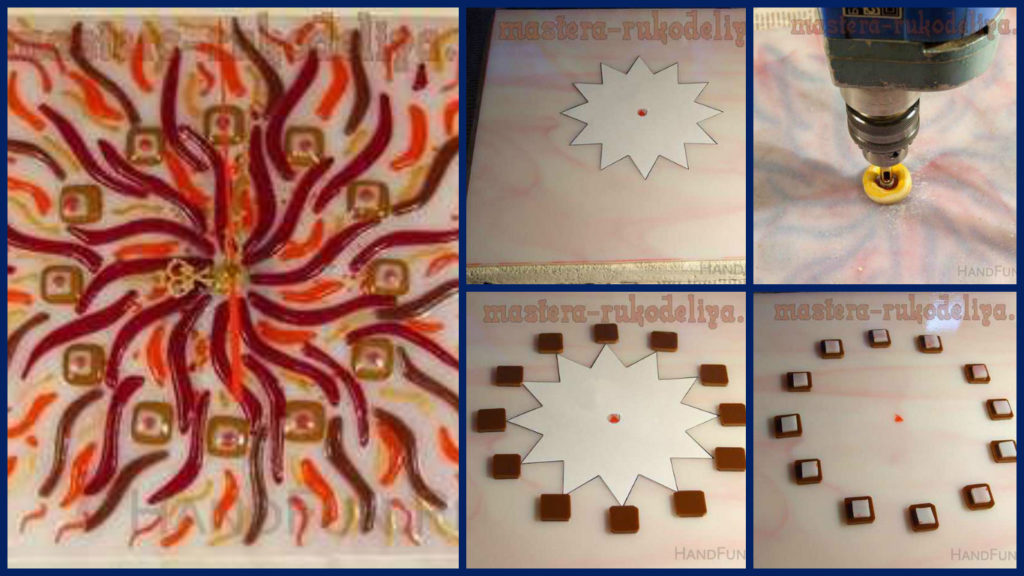

clocks “Fire Flower” by fusing.

As always, the main task of this master class to show everybody passionate about the beautiful products made of colored glass, which, as they say, “no gods pots”, “the devil is not so terrible as his baby”: -), and so on …

At this time, I wanted to do something summer, bright, fiery … So the idea of “Fire Flower”. Especially that all elements of the product are quite simple. To begin, I cut square billets (size 27 x 27 cm) of a pale pink glass with a pattern. He outlined the center of the square a permanent marker and put a twelve-pointed star, which indicates the position of the rays squares tags, symbolizing the number of hours.

Turned workpiece bottom up, stuck in place drilling ring of plasticine, I poured some water there. Water is necessary to diamond drill work properly, it does not overheat and prematurely does not crumble. I, accordingly, was not breathing glass dust, which, by a strange coincidence, health does not add …: -)

Perhaps there should be added, he cut glass process glass cutter glass dust does not produce harmful is not. But we have to work with glasses, so that when the glass breaking of the possible fine particles is not flown into the eye. If you do not wear glasses, you can use the operating safety glasses with regular glass, which you can buy at any hardware store (or store tools) for 20 to 30 rubles.

Since the composition of hours there is a lot of bright shades of red, black clock hands (hour and minute) “lost,” so I have them painted in yellow gold color from spray cans.

For those who still do not know: stained glass is necessary for any item on the fusing technology used with the same coefficient of linear expansion, so that when the cooling of the product is not cracked due to the reduction in the size of different items in different products.